by Michal Stříbrný & Lucie Vlčková

From November 14–26, 2012, selected objects from the UPM’s collections were scanned in 3D, with a total of 245 digital images produced. The anticipated 400 objects could not be scanned during this limited period, and in the course of the work the selection of the items for scanning had to be modified due to technical requirements. The intended choice from the museum’s glass collection was partly replaced with metal ware, textiles and book bindings in a way that provided both a sufficient variability of materials and the presentation of important artworks. Logistically, the “ad hoc” changes of selected objects were quite demanding, due to the independent administration of the museum’s individual departments and their storage rooms. This required that a considerably larger number of workforce had to be involved than had been anticipated. Furthermore, art conservators had to be consulted because certain scanning procedures (notably, turning some objects upside down, or placing them on their upper edges) entailed the risk of possible damage. Therefore, in an effort to eliminate these risks, UPM’s technical team made available professional equipment for stabilizing the objects during scanning. The following summary of the practical experiences and technical problems provides useful information for other Partage Plus partners who are preparing for 3D scanning.

Risk-prone Types of Objects for 3D Scanning Using the Artec D MH Manual Scanner

Glass:

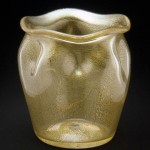

The positive outcome of 3D scanning depends on the type of material, method of execution and decoration of the scanned objects. Transparent glass cannot be scanned well (Fig.1). Coloured glass lends itself better to scanning, but this depends on the degree of the glass’s transparency. When a scanner shines through the glass, the device fails to capture points in space correctly. Similarly, materials with a highly glossy surface deflect flashes of light emanating from the scanner, which generates distorted pictorial information (Fig. 2). A problem can also arise with glass containing tiny glimmering particles that deflect the light produced by the scanner (Fig. 3). When a glass item is decorated with tiny, raised details, this also makes scanning difficult (Fig. 4). Glass adorned with very small textured motifs (Fig. 5) is equally unsuitable. With ceramic objects, problems can be caused by exceedingly shiny glazes.

Base and precious metals:

Metal is a material that is quite suitable for 3D scanning. Surprisingly, the high shine of objects made of precious metals is not a major problem. Small engraved decorative motifs or small parts in relief can be more problematic (Fig. 6). Difficulties appear when scanning objects made of combined types of materials, such as metal and glass, especially in the case of metal-made jardinières, vases or pitchers with clear glass inserts. In such instances, the scanner will capture in detail the metal parts of the object, but will fail to record the variety of shapes of its glass sections (Fig. 7). Small-size items that include most types of jewellery are too detailed to be scanned (Fig. 8). When it comes to silverware, handles can be scanned, whereas knife handles or the ends of fork prongs are too narrow to be shown properly by the scanner. Here, the possibility arises to scan sets of flatware in their cases (Fig. 9). When mirror frames are scanned, the reflective surface needs to be covered with paper or a piece of cloth, which is removed during the subsequent modification of the 3D model on the computer. Should bottoms of objects be scanned to capture particular details that the scanner could not record from above or the side, loose pieces need to be removed from the item that could fall of when turned upside down (clock pendulums, etc.).

Textiles:

Only a few textile items were scanned in the museum. Hats and shoes are suitable for scanning. Conversely, small, intricately-rendered textile pieces, such as laces, fans, etc., fall under the category of objects unsuitable for scanning.

Books:

Book bindings were scanned with no problem whatsoever. A problem can occur with books that are very thin or decorated with tiny details, but in most cases this material lends itself nicely to scanning. During 3D scanning, the objects are placed on a rotating table. Some objects also require scanning from below. With objects of varied shapes, such as vases, there is the risk that when turned upside down they will lose their stability and tip over. In order to secure hollow-ware in the upturned position, the museum’s technical team devised a wooden stand with extension pieces (Fig. 10) which, after the scanning had been completed, was presented as a gift to the Steinbichler Optotechnik company for further use.